.jpg)

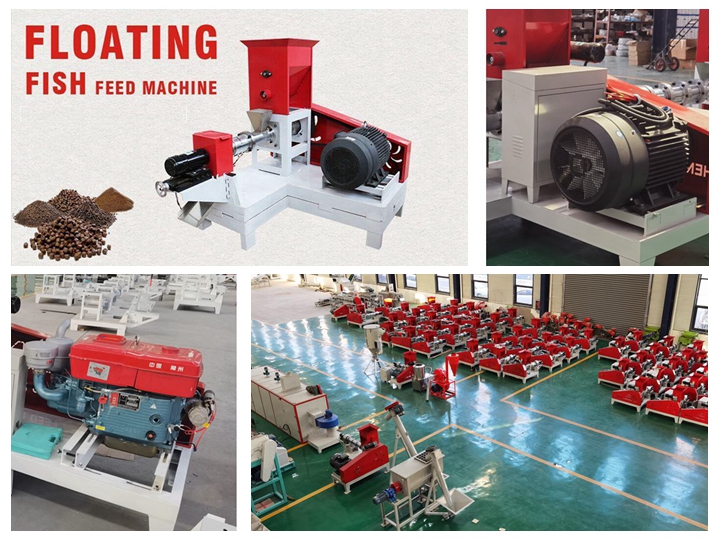

The superiority of our Fish Feed Pellet Extruder. 1. This fish feed-making machine, made from alloy steel, has a stable structure, lower noise, small occupation, and easy operation, all of which make it popular among the farmed fish industry. 2. For a dry-type fish feed-making machine, there is no need to add additional water to the machine, so

.jpg)

Apr 1, 2001 · Conclusion. Both pelleting and extrusion have found a niche in the manufacture of aquatic feeds. Pelleted feeds are largely confined to sinking aquatic feeds such as those for shrimp, trout, and others where the fat requirements are below 12 percent. Extrusion, on the other hand, can provide feeds for these species plus those that require

The technology used in fish feed production is continuously evolving, driven by the need for efficiency, quality, and sustainability. From fish feed extrusion technology to automated production systems, these advancements ensure that fish receive the best possible nutrition, promoting healthy growth and supporting the aquaculture industry’s

Floating Fish Feed Extruder Introduction Fish feed extruder is primarily used for producing high quality puffing pellets for fishes like catfish, carp, tilapia, salmon, trout, and aquarium fish, etc. A wide range of raw materials contain cereals, fish meal, soybean, other vegetable protein meals, fats and oils can be processed into pellets by.

1.Dry type fish feed extruder does not need the steam boiler, so the dry type fish feed pellet machine is cheaper and easier to use and operate.

.jpg)

Fish feed pellet extruder, also known as a fish feed pellet machine or fish feed extruder, is a piece of equipment used in the aquaculture industry to produce high-quality fish feed pellets. These machines are essential for the efficient production of fish feed, whether for small-scale or large-scale fish farming operations.

First, let’s understand floating fish feed pellets’ advantages over sinking feeds. The extruder’s screw cooks the material at 120-175°C for about 30 seconds. This enhances digestibility, inactivates enzymes, and increases starch gelatinization. Thus, the feed breaks down slower in water, allowing fish more time to eat.

.jpg)

The physical feed quality is critical in enabling the feed to provide the desired nutrition and energy to the fish. Some of the common quality issues are feed integrity, non-uniformity of feed sizes, unable to attain the desired level of floatability (in case of floating feeds), dust creation from feeds, oil leakage, rancidity issues, and raw

.jpg)

Gupfenstrasse 5. Uzwil. 9240. Switzerland. Contact us. Bühler’s aqua feed production solutions include complete plant design and installation for producing a full range of fish feed pellets, including floating, sinking and slow sinking feed for shrimp, salmon, trout, seawater fish and more.

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

Favorite Fry Food: Aquarium Co-Op Easy Fry and Small Fish Food. I’m really into breeding nano fish right now, so this fine-grained food is perfect for both the adults and babies in my aquariums. I like that it contains salmon, spirulina, and kelp with high percentages of crude protein (55%) and crude fat content (18%), which is great for

.jpg)

Apr 1, 2004 · Fig. 1: Zones of a single-screw extruder. Fig. 2: Protein molten phase and swollen starch granules. Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey.

.jpg)

Fish Feed Pellet Machine Plant Price,Fish Feed Extruder Fish feed extruder is widely used for producing variety materials into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc. The final feed pellets have unique shape and good taste, high nutrition and smooth textures. 316L Fish Feed Pellet Extruder Machine Parts High quality 316L Fish []

aquarium fish food extruder 1.animal feed processing machine Introduction: Fish feed extruder includes steam methord machine and dry methord machine. In this article, two methords fish feed machine will be introduced. Dry methord floating fish feed pellet machine includes two series. One series is DLG serie single screw extruder fish feed machine.

.jpg)

Jun 25, 2019 · One of the main differences between pelleted and extruded feed is that, whereas pellets sink, the buoyancy of the extruded feed can be controlled during the manufacturing process. However, extrusion has other advantages that we will now examine. Both manufacturing processes have common phases, but the pelletisation or extrusion phase is the one