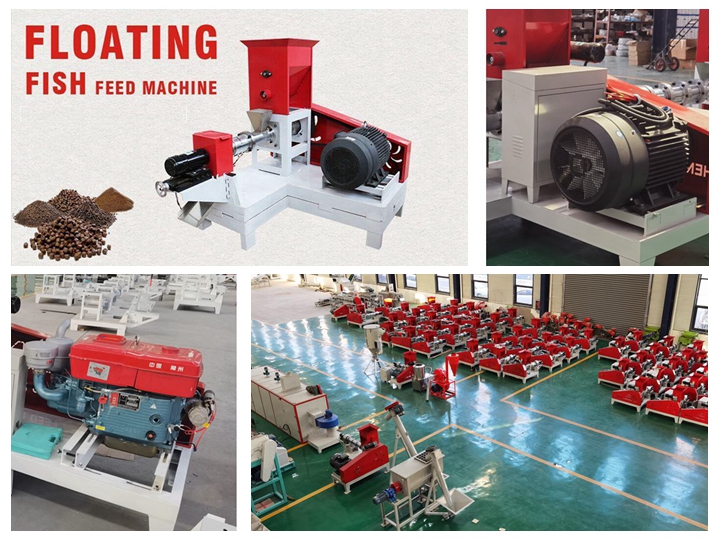

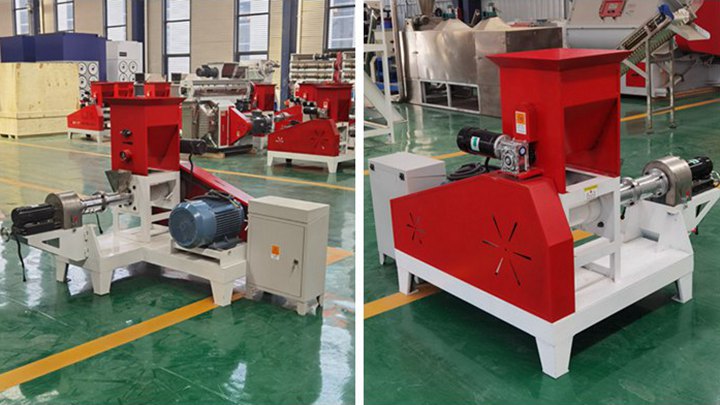

Fish feed making machine is the main pelleting machine that pressed the crushed material and nutrient solution into fish feed pellet, suitable for catfish,shrimp,crab,trout,sturgeons,carp,pangasius,white fish,etc aquaculture

SZLH508 animal feed pellet making machine models can offer the possibility of pelleting animal feed in capacities between 10-18 tons/h. RICHI has series animal feed pellet making machine for sale more than 130 countries, they can work in small and massive facilities in optimal capacity regarding your needs.

.jpg)

Best Quality Floating Fish Feed Pellet Mill Making Machine. The fish feed pellets can float on water for over 20 hours.And sinking and floating aqua-feed pellets both can be made just by adjusting the feed formulation. 2). Pellet diameter is 0.9mm-15mm by changing the mold. Floating Fish Feed at Best Price in India. Company Video. View Mobile

.jpg)

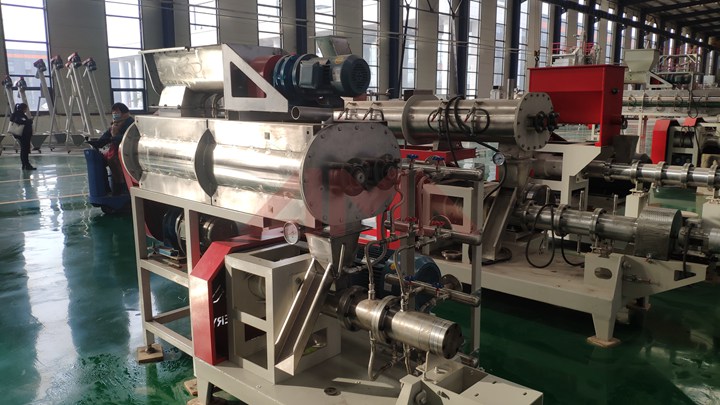

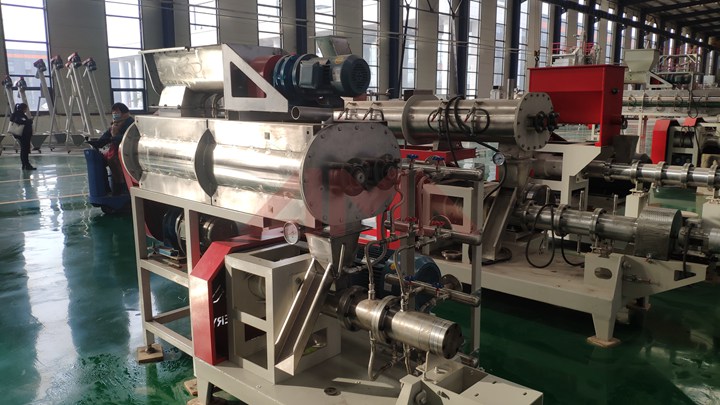

This used to produce large amounts of animal feed. A small scale pellet mill simply processes dry powder into pellets using a flat die, it does not grind and mix. This kind of pellet mill can produce anywhere between 80 to 1000 kilograms of pellets per hour. Flat Die Cattle Feed Pellet Mill for Sale. Electric machine : Movable machine with

Flat Die Pellet Machine, Ring Die Pellet Machine, Feed Pellet Mill manufacturer / supplier in China, offering Agricultural Cow Feed Grass Chaff Cutter Machinery for Poultry Feed Processing, China Low Cost Sale Farm Home Use Mini Sawdustfish Small Grass Biomass Pellet Press for Making Ricehusk, Hay, Cotton Stalk, Best Price Sale Farm Home Use Mini Sawdust Biomass Smallfish Pellet Press for

Specialize in cutting-edge animal feed production machine for pellet, mash and extruded feed production. Explore our solutions!

Sep 20, 2023 · Table of Contents. 15 Best Livestock Feed Pellet Making Machines. Pellet Mill SZLH Series – Price Ranges from $5,000 to $50,000. Flat Die Pellet Mill – Price Ranges from $200 to $3,000. Ring Die Pellet Mill – Price Ranges from $10,000 to $100,000 or more. Vertical Ring Die Pellet Mill – Price Ranges from $10,000 to $50,000.

.jpg)

Why Choose GEMCO Animal Feed Pellet Machine? feed-pellet-mill-manufacturer-GEMCO. Low cost, convenient operation and maintenance; High yield, energy-saving and environmental friendly; Designed by GEMCO research and development team; Nearly 30 years experience in feed pellet mill manufacturing, installation and commissioning

Fish feed pelleting machine price usually ranges from 3,000-200,000 USD, mainly used to process pellet feed for fish, shrimp, pet, etc.

The feed pellet industry’s growth has made chicken feed pellet machine increasingly popular for breeding. Their benefits include a simple structure, small footprint, favorable price, and low consumption, making them ideal for small industrial production, chicken farms, and large factories.

China Animal Feed Pellet Mill Machine wholesale - Select 2024 high quality Animal Feed Pellet Mill Machine products in best price from certified Chinese Pelletizer manufacturers, Feed Pellet Machine suppliers, wholesalers and factory on LimaFeedPelletizer.com

.jpg)

Animal feed pellet mill machine for sale,making rabbit cattle feed pelletAnimal feed pellet mill is mainly used for small-scale production of animal and poultry feed pellets, it’s + 8617337771729

Application: Fish oil,Fishmeal,Soya protein,Wheat gluten,Wheat and peas, etc. pellet dia: 0.9-10mm. customized. 60-5000kg/h. 1 year. Make feed pellets for all kinds of fishes, suitable for fish pond holders and feed pellet manufacturers. 200-300kg/h Small Feed Pellet Line.

Find here Feed Pellet Making Machine, Feed Pellet Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Feed Pellet Making Machine, Feed Pellet Machine, Animal Feed Pellet Mill across India.

Here, we provide a hammer grinding machine – fish feed hammer mill for processing feed stuffs of various granularity into small pieces. And here is the working principle of this machine: hammer hit breaks raw materials in the crushing chamber with high-speed rotation; then the broken materials move with continuous friction and crash against the hammer, toothed plate and sieve for crushing.