The cost of feed pellet machines in Ethiopia varies widely, primarily influenced by factors such as machine capacity, features, and import costs. For small-scale operations, affordable models are available, though they may have limited features.

RICHI MACHINERY. Founded in 1995, Richi Machinery has been developing steadily and steadily in the field of pellet processing. It is mainly engaged in the R&D and manufacturing of pellet plant equipment required for industry projects such as feed, biomass energy, and organic fertilizer.

Primarily, there are two main types of sawdust pellet mill: Flat Diefish Pellet Machine and Ring Diefish Pellet Mill. you can compare in detail about flat die vs ring die pellet mill. Each comes with its own set of advantages and disadvantages, as detailed below:

.jpg)

The PM 1850 pellet mill is the heart of biomass reduction and material densification systems for agriculture, recycling, and manufacturing. Three-phase power drives an 18.5″ machine-hardened die. LEARN MORE

.jpg)

Jan 10, 2024 · In conclusion, animal feed pellet machines play a crucial role in the animal feed production industry by converting raw ingredients into high-quality pellets. Their efficient operation, ability to produce uniform feed pellets, and numerous benefits make them an indispensable tool for livestock and poultry farms, fish farms, and pet food production.

Sep 20, 2023 · Table of Contents. 15 Best Livestock Feed Pellet Making Machines. Pellet Mill SZLH Series – Price Ranges from $5,000 to $50,000. Flat Die Pellet Mill – Price Ranges from $200 to $3,000. Ring Die Pellet Mill – Price Ranges from $10,000 to $100,000 or more. Vertical Ring Die Pellet Mill – Price Ranges from $10,000 to $50,000.

We have been having intermittent phone issues. Please call or text 715-829-5432 if you have problems. PelletMasters Pellet Mills, Hammer Mills, and Fine Grinders

.jpg)

Feed Pellet Machine Pelletizer Heavy Duty Brand New Shipped and Delivered! Save cost by producing your own feeds from corn, rice, grain, grass, seeds, and many more bio materials. Easy to use plug

.jpg)

Steaming Conditioner Pelletizer Machine for Extruding Fish Feed Pellet Line US$20,000.00-200,000.00 / Piece 1 Piece (MOQ)

.jpg)

Apr 25, 2011 · Wear of machine parts as well as damage to the pellets can be greatly reduced compared with an impact dryer. Given the short residence time on the belt, some kind of post-dewatering drying (such as with a fluidized bed) or additional cooling is usually required. Benefits of this new non-impact pellet-drying solution are:

.jpg)

With the ISEC evo pelletizing machine, you can efficiently process a wide variety of materials to produce high-quality recycled pellets. The powerful machine is easy to operate and delivers more throughput. With the integrated shredder/extruder combination, you transform your production scrap into recycled pellets.

.jpg)

feed pelletizer. For pelleted feed, Buschhoff also provides the right solution. The services offered range from 2 – 20 t/h. For the most part, we build these systems – including the milling and mixing equipment – as single level construction.

.jpg)

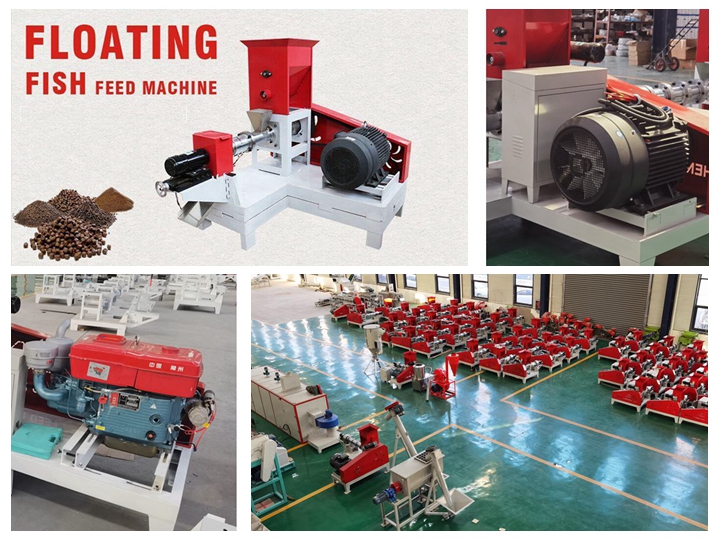

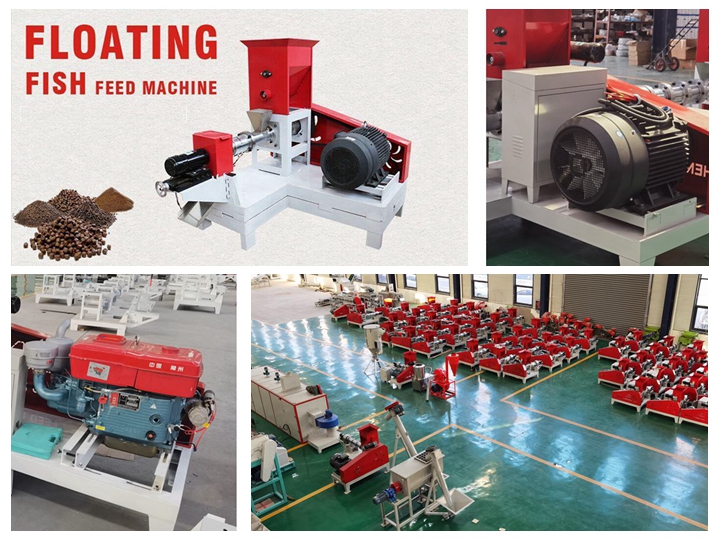

Navigating the cost of fish feed machine in Lagos and other parts of Nigeria can be challenging due to varied options. Prices fluctuate based on the model, capacity, and the manufacturer. Prices fluctuate based on the model, capacity, and the manufacturer.

This project is in Iraq, the capacity is 5 tons per hour. Our company is a professional fish feed production line manufacturer with about 15 years, if you want to build your own fish feed pellet production line, please contact us.

.jpg)

The Japan Dual-Use Automatic Feed Pellet Machine is a high-quality and efficient pelletizer machine designed for both dry and wet feed pellet production. With a capacity of 200-300KG, this machine is perfect for small to medium-scale breeding operations.