.jpg)

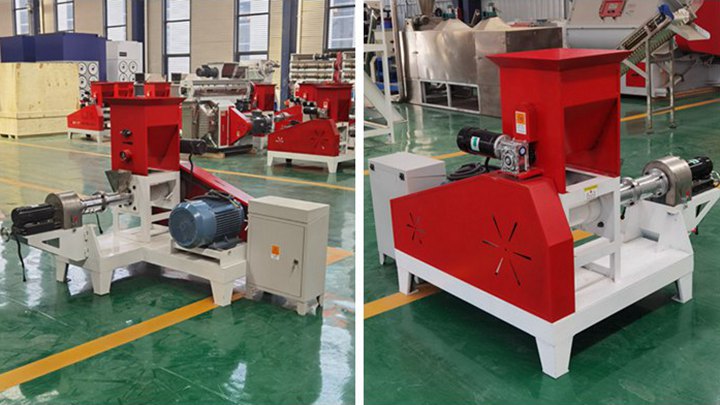

Different output animal feed equipment can be customized according to different feed types and output capacity requirement from clients.We are committed to produce all kinds of animal feed production lines of 1-20TPH, and provice more value-added services for each customer.

.jpg)

The entire poultry feed production line is tailor-made by RICHI senior engineers according to the user’s production requirements. The sand making equipment is reasonably configured, with a short running-in period, a longer effective working service period, and a high return on production. Capacity: 1-160T/H. Price: 10,000-5,000,000 USD.

.jpg)

The formulation of sinking fish feed plays a vital role in the health and growth of the fish. Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency.The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met.

Use a chicken feed grinder or a heavy-duty blender to grind ingredients into a fine, uniform texture. This enhances the digestibility and mixing process. 5. Mixing: Ensure the ingredients are well-mixed to create a homogeneous feed. You can use a large container or chicken feed mixer for this. 6.

.jpg)

The company’s fish feed equipment production line can be widely used in the production of ornamental fish, farmed fish, shrimp and crabs and other feeds. By adjusting the ratio of raw materials, temperature, moisture and other process parameters, it can produce floating feed, sinking feed and partial sinking feed.

Customized Solutions. Our innovation never ceases, and it’s customizable to help you act on opportunities. Introducing the Purina professionals behind the latest poultry research.. Purina® Commercial Poultry Solutions provides a broad spectrum of nutrition, feed manufacturing and poultry production expertise. Learn more.

.jpg)

Jan 4, 2024 · Conclusion. Feed manufacturing processes are a symphony of science and engineering, where raw materials are transformed into nutritionally balanced feeds that drive the livestock and poultry industry. Process engineers are pivotal in optimizing these processes, ensuring efficiency, consistency, and compliance with stringent quality and safety

.jpg)

Fish Feed Making Process. 1. Mix the chicken manure (accounts for about 50%) with proportional corn flour, bean cake, rape seed cake, and wheat bran. 2. Add a certain amount of leavening agent to the mixture (the leavening agent can be diluted with water in advance to be mixed easily and evenly with materials.) 3.

.jpg)

Dec 18, 2019 · Poultry feed manufacturing process flow chart. The processing of composite poultry feed is usually divided into the following steps: receiving and cleaning of raw materials, crushing of raw materials, batching, mixing, pelleting and packaging. The diameter of the final feed pellets can be 2 to 8 mm. This is a multi-functional feed pellet making

50-150 kg/h Fish Feed extruder production Line 200-500kg/h Fish Feed production Line 200-1000kg/h Chicken Feed Pellet Line

.jpg)

As a reliable animal feed machine manufacturer,Lima Machinery are specialized in turnkey feed production project including process design, factory layout, equipment manufacture, feed plant installation and commission, and site training of electric control, plant operation, animal feed processing technologies and formulations.

.jpg)

A 6-8mm raw material size is ideal for sinking fish feed pellets and making cattle, pig, sheep, goat, deer, and rabbit feed pellets. For floating fish feed, use a floating fish feed production line. A 3-5mm size suits cattle, rabbit, pig, horse, deer feed, and feed for animal cubs. The size of the feed pellets depends on the size of the die

Type: SZLH series Animal Feed Pellet Mill Capacity(t/h): 0.5-30 Pellet size(mm): 2-12 Application: Can be used for poultry,livestock,ruminants and aquatic pellet feed production.

.jpg)

Apr 19, 2024 · Complete Poultry Feed Pellet Production Line. Animal feed production lines can be classified based on their throughput capacity, ranging from small-scale operations (2–10 tons per hour) to large

.jpg)

The cost of a Animal Feed Production Line can vary widely depending on its size, capabilities, and complexity. Most of the price of Animal Feed Production Line ranges from US $ 2000 to $ 200000 per Set. It's important to research and compare different models and features to find the best Animal Feed Production Line for your needs and budget.