.jpg)

Nov 2, 2016 · Biomass Pellet Machine (7) Blogs (12) Industry News (66) Products (63) Dry Type Fish Feed Extruder (1) Feed Hammer Mill (2) Feed Pellet line/plant (14) Feed Pellet Machine (9) Fish Feed Extruder (7) Fish Feed Machine (3) Fish Feed Pellet Machine/lines (4) Fish Feed Production Line (5) Floating Fish Feed Machine (3)fish Hammer Mill (3)fish

.jpg)

The fish feed production plant they built has an output of 2t/h, and the fish feed manufacturing unit for freshwater fish food pellets production occupies an area of 8M*11M*14M (L*W*H). It is worth mentioning that this is the first phase of the Bolivia customer's floating fish feed plant project for tilapia pellets.

.jpg)

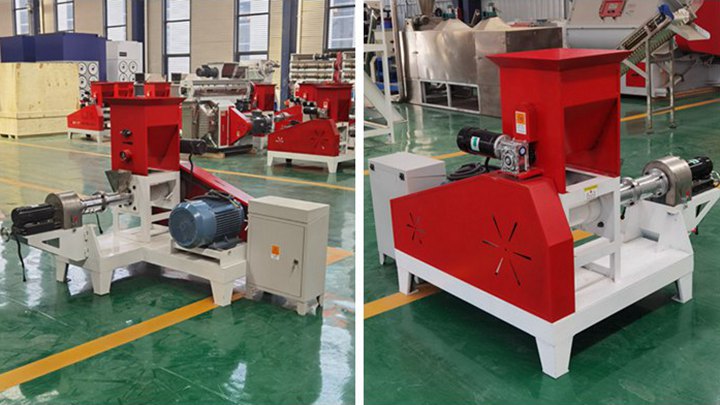

Our floating fish feed-making machine can produce different shapes of pellets through different molds. Customers can choose molds according to their needs. The fish pellet making machine models are complete from 400KG per hour to 2 tons per hour, we have different models to meet the needs of customers. The electric heating device is used to

.jpg)

The 7.5t/h sinking fish feed manufacturing plant project covers an area of 20,696.0 m², with a construction area of 23,014.4 m². It is mainly engaged in the processing and production of aquatic feed, with an annual production scale of 18,000 tons of aquatic feed. Production scale: 2 fish food production lines.

Snacks Machinery | Pet Food Machines - DEJIU. Shandong Dejiu Machinery Co.,Ltd. is a manufacturer with 15 years experience in snacks food machine,we provide snacks food machine development, manufacturing,sales and after-sales service. 0086 13256660088 info@ dejiumachinery.com. Get Price.

2023-2-10·Features of fish feed machine line: 1.Fish food made by this pellet extruder is of puffing type, more easily to digest for fishes, and our company provides various feed formulas to meet the nutritional needs of different fish and different stages of fish. 2.The fish feed pellet size can be from 0.9-10mm to feed different sizes of

.jpg)

Small Scale Fish Feed Pellet Making Machines at Factory Price. Raw Material Preparation. The first step is to gather the necessary ingredients for the feed formulation. Common ingredients for fish feed pellet making include fishmeal, soybean meal, wheat flour, fish oil, vitamins, and minerals.

Our small biomass pellet machine stands for sustainability and efficiency. It is one of the most important machines in the biomass pellet plants. They are simple and solid machines, with high reliability and very low maintenance costs. Capacity: 0.3-4.0 T/H. Power: 37KW.

Industry leading 2 Year factory Warranty, Over 30 years experience, contact ELF Systems today. Pellet Mills for sale in Canada, USA & North America. Turnfish, biomass, feed, plastic, hops & hemp into pellets with ELF Pellet Making Machines.

.jpg)

Taizy Machinery is a professional manufacturer & supplier of the fish food pellet machine, very popular at home and abroad. Phone +86 13673689272 E-mail info@fishfoodmachinery.com

.jpg)

The 3-4t/h floating fish feed extruder machine with good control performance can effectively guarantee the quality of floating fish extruded pellets, stable and reliable. The new generation of multi-screw coaxial continuous extrusion makes material mature more uniform and discharge smoother. Main power: 90 kw.

.jpg)

Feb 11, 2021 · I made diy fish food for my koi and goldfish with my own food mixture, fish color enhancer, spirulina and honey

Floating Fish Feed Extruder Machine 3-4T/H. Floating Fish Feed Pellet Making Machine 4-5T/H. Floating Fish Feed Pellet Mill 6-7T/H. Fish Feed Pellet Extruder 8-10T/H. Floating Fish Pellet Machine For Sale 10-12T/H. Sinking Fish Feed Machine. Menu Toggle. Fish Feed Processing Line. Sinking Fish Feed Pellet Mill 0.6-1.2T/H.

.jpg)

fish feed pellet machine price 1416 products -Lima.com offers 1416 fish feed pellet machine price products. About 53% of these are Feed Processing Machines, 0% are Tray Dryer, and 1% floating fish feed pellet machine, floating fish feed pellet2575 products -Lima.com offers 2575 floating fish feed pellet machine products.

.jpg)

Each step, from fish feed making formula to extrusion and processing, affects the nutritional value and quality of the pellets. Understanding every key step and the associated considerations is essential to ensure the quality and nutritional balance of feed pellets.