.jpg)

ABOUT OUR COMPANY. Our factory established in 2012. Our manufacturing factory is more than 6000m², workers more than 60 person. Our working team have experienced more than 10 years on extrusion processing.

Processing and Application of Floating and Sinking Fish Feed. With the further development of the fish farming industry, extruded fish feeds have obtained more and more wide applications in virtue of unique advantages including high nutrients, good palatability, strong digestibility, and so on. As a new technology to produce feed, extrusion

May 20, 2011 · The following list summarizes the advantages to be gained through using cold extrusion: 1. Nutrients are not subjected to high levels of mechanical shear and temperature. This maximizes bio-delivery of nutrients and minimizes recipe costs where now excess nutrients are added to compensate for process damage. 2.

.jpg)

Our pet food production line has novel design, compact structure and high production efficiency; The dog grain machine is simple to operate, durable and has low failure rate; The dog food making machine can process 1-15mm deep fried round products and PET particles of various shapes and sizes (molds are distributed as required).

.jpg)

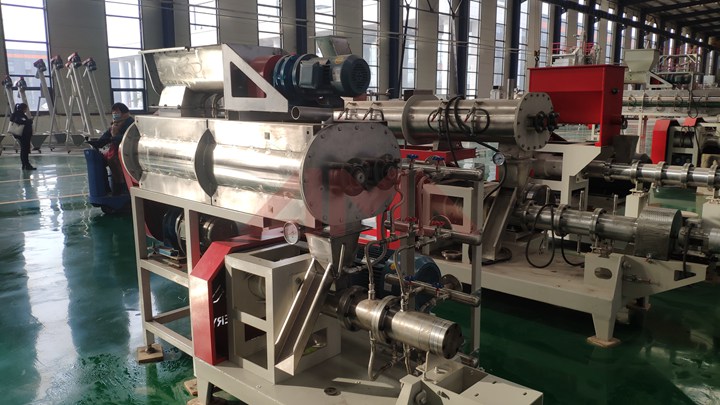

The commercial fish feed extrusion process refers to cooking the mixture of feed ingredients under high temperature, moisture, and high pressure by means of a fish feed extruder within a short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet extrusion).

.jpg)

Food extrusion is a form of extrusion used in food processing. It is a process by which a set of mixed ingredients are forced through an opening in a perforated plate or die with a design specific to the food, and is then cut to a specified size by blades. The machine which forces the mix through the die is an extruder, and the mix is known as

Apr 18, 2024 · A food extruder operates by feeding a mixture of ingredients into a chamber where they are heated and compressed by a rotating screw. The pressure generated forces the mixture through a die, shaping it into the desired form. The extruded product is then cut to the desired length and cooled for further processing. 3.

.jpg)

This extrusion in food processing technology allows the production of puffed, organized, or unbuffed products. Currently, food extruder machines have become the choice of many food processing companies due to their ease of use and cleanliness, the long shelf life of the food, the fact that the shape of the food can be designed at will, and the ease of operation.

.jpg)

Apr 1, 2004 · Fig. 1: Zones of a single-screw extruder. Fig. 2: Protein molten phase and swollen starch granules. Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey.

Amazing floating fish feed extruder machine in nigeria At. DGP40 fish feed machine manual small electric floating fish feed extruder machine in nigeria US $1869-$1899 / Set 1 Set (Min. Order) 9 YRS Henan Strongwin Machinery Equipment Co., Ltd. 97.9% 4.9 (7) “Outstanding service” Contact Supplier 1/2 fish,cat,dog.

.jpg)

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

.jpg)

Clextral extrusion systems efficiently produce high-energy feed with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility. Extruded feeds are produced to match fish feeding habits (floating, neutral buoyancy or sinking) to energize feeding and reduce waste. We offer an output range from 25 to over 34,000 kg

Oct 1, 2001 · The internal fat level was adjusted by continuously injecting fish oil into the preconditioning phase of extrusion system at 0, 0.9, 1.8, 3.6, 7.2 and 14.4 percent levels. As the internal fat addition increased from 0 to 14.4 percent, bulk density of the extruded product increased and external fat absorption decreased (Fig. 1).

.jpg)

Sep 25, 2022 · Extrusion produces consistent results - Food extruders produce consistently high-quality products by pushing hot air or liquid through a variety of substances, such as dough, batter, or pizza sauce. This prevents ingredients from clumping together or forming lumps, which in turn gives foods a smooth texture and uniform color. 2. Extrusion is