.jpg)

dry type crab feed extruder machine in Ghana-Feed Pelleting Machines Dry Type Fish Feed Extruder Vs Wet Type Fish Feed MachineThe dry type fish feed extruder is mainly used for the production of aquatic feed, such as making fish feed pellets, tilap Email:lima37@limamachinery-Lima Mobile: 8619337889051 HOME Products Feed crushing machine

large scale carp pellet machine in Ghana-Fishfeedextruders dry-way fish feed pellet making machine Ghana for advancedSinking Fish Feed Making Machine.Lima is a professional fish feed machine manufacturer. We help small, medium and larg Email: lima37@limamachinery-LimaTel: 8619337889051 Home Products Feed crushing machine

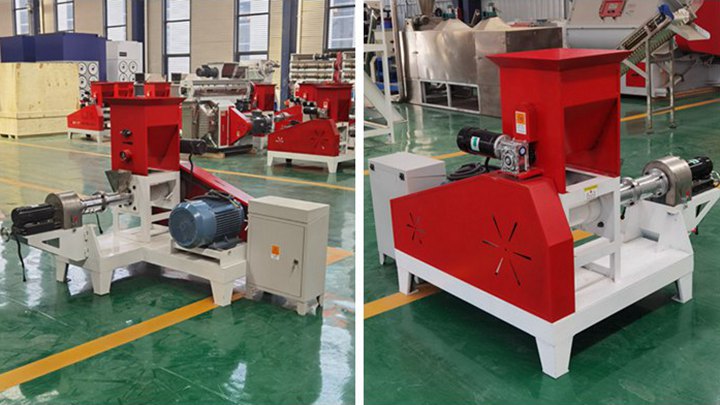

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes. Get Price dry-way fish feed extruder machine Ghana for supplier

.jpg)

ZSK Food Extruders Process Innovation for Meat Analogue Extrusion. The outer to inner working screw diameter of Coperion’s ZSK Food Extruder is 1.8, making it the highest free volume extruder on the market. This ratio remains constant for the different extruder sizes, which is vital for scale-up.

Food extrusion is an established and highly versatile technique for the production of food, feed, nutritional additives and flavors. It enables a continuous and cost-effective means of production, and its precise control ensures a high and constant product quality. Different extruder dies are available to shape foods with high starch content

Coperion’s twin screw extruder ZSK Mv PLUS provides ideal conditions for the extrusion of many types of food and pet food products. The process section of the ZSK twin screw extruder consists of several barrels in which the co-rotating screws operate. The closely intermeshing screws with their tight selfwiping profile eliminate stagnant zones

Jul 1, 2017 · Food extrusion was developed in the 1930s for dry pasta and breakfast cereal pellet production. In the 1950s, it was applied for pet food manufacturing. Over the past 80 years, applications of continuous extrusion processing have expanded as the technology has been developed as an alternative method for texturization, mixing, forming, reacting

.jpg)

Aug 4, 2023 · There are three types of extruders used by food manufacturers in snacks industries. These are piston extruders, roller-type extruders, and screw extruders (Alam et al., 2016). Screw extruders are most likely used now days. On the basis of screw design, two types of extruders are most commonly used: