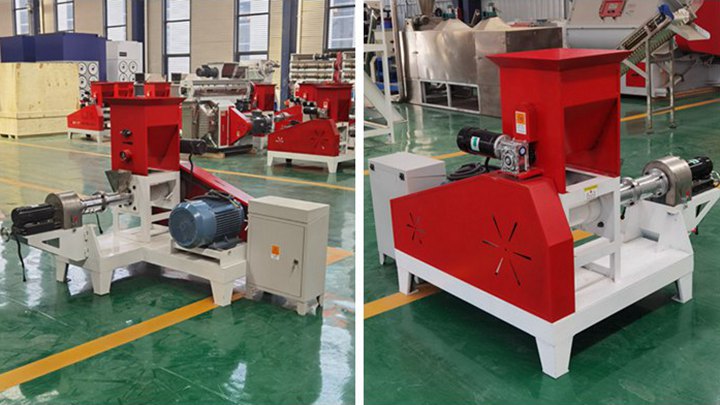

Fish fish feed extruders factory in the Philippines. 200kg/h fish feed extruder machine Feed size 3 mm Philippines2023 Pellet Size 1-12mm Animal Floating Fish Feed Pellet Making Machine 180-200kg/h Pet Food Mill Extruder Machine in Email: lima37@limamachinery-Lima Tel: 8619337889051. Get Price.

.jpg)

small fin fish feed extruder in the Philippines-Feed Pellets Mill This small fish pellet extruder machine can make different size pellet.can feed fish, dog,cat and othe animal.The pellet can floating about 12 hours.pellet size 1-10mm can choose.

.jpg)

Brand new twin screw extruder machine rabbit Philippinesbrand new margo make pvc pipe plant mts-450. 1 prime margo twin screw extruder - mts-450. output :450 kg/hr. with delta plc Email: lima37@limamachinery-Lima Tel: 8619337889051

.jpg)

There are 2-types of counterrotating twin screw: the intermeshing type and the non-intermeshing type. Get Price. dry type twin screw extruder machine catfish Nigeria. The twin screw extruder machines are used for the plastic extrusion process when two or more ingredients are mixed or compounded.

.jpg)

dry type twin screw extruder machine white fish Philippines Cost-efficient Fish Feed Machine of Top Quality 2023/11/28 · This dry type floating fish feed machine is an ideal for small and medium fish farm holders or feed processing plant.

The twin-screw is made of high temperature and wear resistance materials, and extruder barrel adopts high-quality steel. Fish Feed Dryer. It is a kind of net-belt drying machine that can achieve batch and continuous production, of which heating mode include electric heating, steam heating and hot-air heating.

Evolum+ twin-screw extruders are equipped with advanced technology to give our customers new levels of throughput, flexibility and control while ensuring optimum process stability and maximum food and non-food product quality. Profitable performance

Robust gearbox ensures low maintenance costs and long service life. Optimized screw geometry. Standard metering for processing a wide range of materials. Rectangular feed opening enables optimum screw filling. Long preheating section for high process flexibility. 32D processing unit with molybdenum-welded screws and deep-nitrided, air-cooled

The twin screw extruder ZSK MEGAcompounder from Coperion is considered a milestone in the development of the high-performance compounding plants for the production of polyolefins. The extremely high productivity of the system is the result of more than 60 years of continuous research and development. The ZSK MEGAcompounder series is ideally

.jpg)

As a pioneer in the development of the closely intermeshing, co-rotating twin screw extruder, we possess a unique know-how and an extraordinary wealth of experience in this field. Coperion has continuously set new standards in machine and system design for processing technology since the 1950s. More than 15,000 installed compounding systems

.jpg)

Twin-screw extrusion (TSE) is the standard for mixing and compounding in polymer processing and has expanded into other applications for new material development. TSE offers a high level of process flexibility, more control of process parameters, and can produce a wider range of products.

.jpg)

Summary Extrusion at higher moisture contents (. 40%), also known as wet extrusion, is relative-ly less investigated compared to low and intermediate moisture extrusion. Literature on high moisture food extrusion has been reviewed. Wet extrusion applications utilise twin screw extruders due to their efficient conveying capabilities.