.jpg)

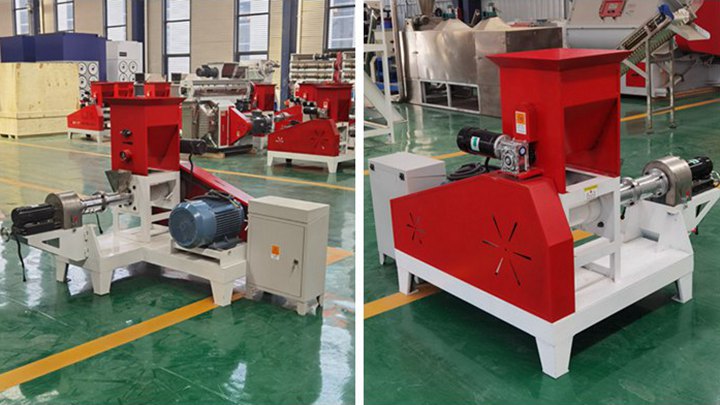

Two fish feed machines, dry and wet type extruders, produce floating feed. The dry type makes feed for fish, tilapia, catfish, shrimp, crab, turtle, and goldfish. It extrudes pellets at high temperature.

.jpg)

The fish feed pellet extruder can be divided into two types: dry type fish feed extruder and wet type extruder. Fish Feed Extruder, Floating Fish Feed Pellet Machine. Floating Fish Feed Extruder Introduction Fish feed extruder is primarily used for producing high quality puffing pellets for fishes like catfish, carp, tilapia, salmon, trout, and

.jpg)

The final products have unique shape and good taste, high nutrition and smooth textures. For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment. This dry type floating fish feed machine is an ideal for small and medium fish farm holders or feed processing plant.

As an upgrade of the DGP series, the LX series fish feed extruder uses high temperature, high pressure and shearing force to cause physical and chemical changes in the starch and protein in the feed through short-term high temperature and high pressure treatment, thereby improving the solubility and digestibility of the feed.

The wet-type fish feed extruder machine is widely used in making both floating fish feed and sinking feed pellets for aquaculture farms, feed mills, livestock farms, and poultry farms. Different from the dry type floating fish feed pellet mill, the wet type is equipped with a boiler that can continuously steam the materials to make pellets. It

.jpg)

Equipment – Fish Feed Extruder. Currently, the main extrusion equipment applied in aquatic feed production is a single screw fish feed extruder which is also divided into dry type fish feed extruder and wet type fish feed extruder machine. With different parameters and feed formulation, fish farmers and feed plants can make floating, sinking

Lima offers two types of fish feed extruder. They are dry type fish feed extruder and wet type fish feed extruder. For small and medium-sized users, dry type fish feed machine is better and more economical, and wet type fish feed machine is suitable for large fish pond holders and feed pellet manufacturers. You can choose according to your needs.

Sep 5, 2016 · In recent years pellet feed becoming popular.Many fish farms choose our dry type fish feed extruder to make fish feed pellets by themselves.You can make the floating or sinking fish feeds with different diameters and shapes easily.

.jpg)

Start with dry type fish feed extruder,pellets diameter is 0.9-15mm and floating time is >12hrs. Wet Type Floating Fish Feed Extruder. October 15th, 2018 | 0 ...

This floating fish feed extruder machine, also called floating fish feed pellet mill, is mainly utilized for making floating fish feed pellets or sinking, slow sinking fish feed for catfish, aquarium fish, shrimp, tilapia, red or black porg

.jpg)

Therefore, lots of fishermen decide to produce the floating or sinking fish feed by themselves via using wet or dry type fish feed extruder. Usually, for small and medium-sized size farms, we suggest choosing the dry-type fish feed pellet extruder because without a steam generator for heating, a dry fish feed extruder is much cheaper than a wet

This Floating Fish Feed Pellet Making Machine is widely used for producing maize flour, soybean flour or compound powder, wheat bran into high grade aquatic feed pellets for fish, catfish, shrimps, dog,.cat etc.

.jpg)

There are two floating fish feed pellet machine types: dry type and wet type extruders. We focus on dry type floating fish feed pellet machine here. The single-screw, dry type machine produces floating fish feed pellets for fish, tilapia, catfish, shrimp, crab, turtle, and goldfish. High temperature in the floating fish feed pellet machine

Extrusion with steam preconditioning is known as the wet-type fish feed extruder. The wet-type processing needs a boiler to make steam for the conditioner and ripen the raw material in advance. Dry feed pellets are stable for relatively long periods, for convenient storage and distribution.

The differences and features of the dry type and wet type extruder: 1. Dry type fish feed extruder does not need the steam boiler while the wet type is with the conditioner and need to equip the steam boiler. So the dry type fish feed pellet machine is cheaper and easier to use and operate. 2.