Sep 6, 2022 · Briefly, fish feed extrusion process requires a fish feed hammer mill to grind raw materials, mixer to blend raw materials including vitamin-mineral premix, the wet type fish food extruder machine with steam preconditioner (yes, steam is equired for quality pellets) and cutter head to shape the pellets, and finally a dryer-cooler to ensure

.jpg)

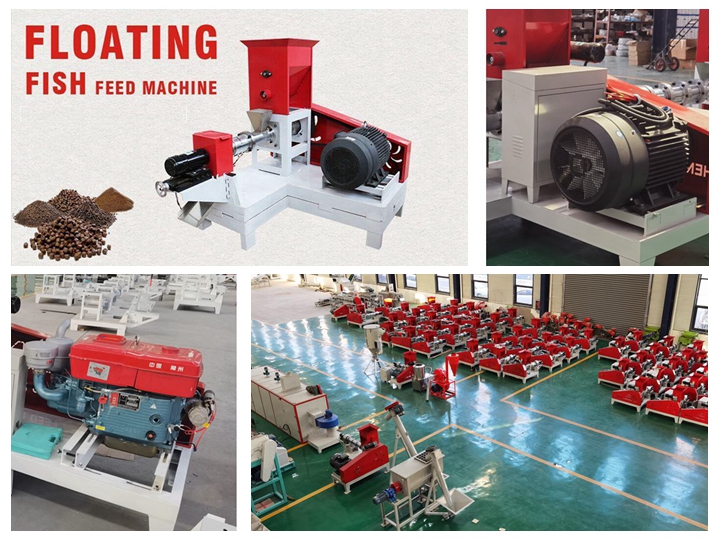

Nowadays, Taizy fish feed pellet extruder has become the first choice for many farmers to produce high-quality feed pellets in the growing aquaculture industry. Our fish feed pellet machine stands out for its outstanding performance, versatility and commitment to quality and sustainability.

Types of fish feed pellet machines in the Nigerian market. The fish food pellet mills currently for sale in Nigeria by our company cover a wide range of models, including small family farm-ready models to large industrial-grade fully automated lines, with outputs ranging from 40 kg per hour to 1,000 kg per hour.

And now the two-section spiral fish feed extruder is the cheapest floating fish feed pellet machine. In all respects, the two-section screw fish food extruder is also the most popular with customers. At present, we have sold the two screw fish feed pellet machines to countries around the world, such as Malaysia, Nigeria, Mali, Niger, Cameroon

The floating fish feed machine is to convert soybean meal, rice bran, fish meal, bone meal, corn meal, flour, etc. into fish feed pellets with various shapes by heating and extruding. It has a capacity of 40-350kg/h, even bigger.

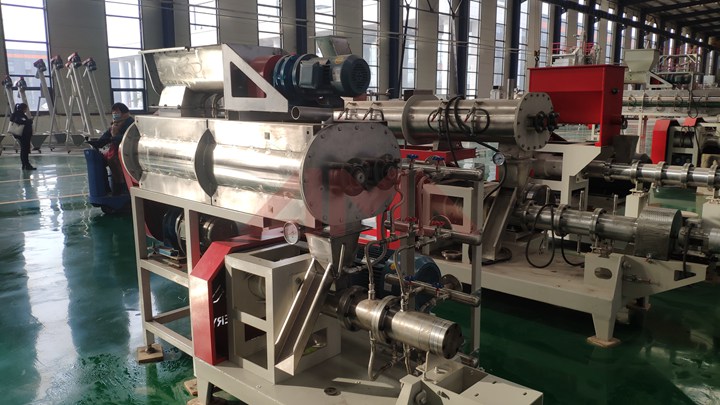

RCPH120*2 floating fish feed extruder machine is the third generation of new twin-screw extruder machine developed by Richi Machinery on the basis of digesting and absorbing foreign advanced technology. Its power configuration is 90KW, and the output of processing aquatic feed is 3-4 tons per hour. It can meet the current production needs of

.jpg)

Our wet floating fish feed extruder produces 0.9-12mm pellets, suitable for pet food and animal feeds, including shrimp. We also offer a sinking feed extruder for sink pellets. The machine works with single or three-phase power. It offers capacities from 30kg/h to 5000kg/h, split between small and large scales.

.jpg)

This floating fish feed production line can produce fish food feed of various shapes and yields by cursing, mixing, extruding and drying. It has an output of 40-350kg/h, suitable for small and medium fish farming plants, etc. The produced feeds can be used for the following animals: all kinds of fish, parrots, shrimps, etc.

.jpg)

1. Simple structure, widely used, small flooring space, low noise. 2. We can use dry powder materials to make feed pellets without adding extra water to the dry-type fish feed extruder. The dry pellet feed is convenient to store. 3. The dry pellet feed is well processed which is easy for the animals to digest.

The floating fish feed extruder allows for precise control over the pellet’s size, shape, density, and nutritional composition, ensuring that the fish receive a balanced and high-quality diet for optimal growth and health. This technology is crucial in the aquaculture industry, where efficiently producing nutritious and cost-effective fish

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

.jpg)

The fish food extruder makes the material have a certain shape through the spiral extrusion process. This dry type fish feed extruder has a combination of one or more functions such as mixing, maturing, kneading, shearing, and forming. Put the crushed raw materials into the hopper, and the fish food pellet machine will produce smooth round pellets.

There are many kinds of floating fish feed mill plant— the 1-2t/h, 3-4t/h, 4-5t/h, 6-7t/h, 8-10t/h, 10-12t/h, etc., and these kinds have hundreds of customized designs in total. No matter what demands you put, we can always assemble a floating feed plant for you. Floating fish feed mill cost:80,000-3,000,000 USD.

.jpg)

Function: fish feed pellet processing. Capacity:120kg/hour, 200kg/hour, 500kg/hour, Model: AVN65, AVN70, AVN85 Category: Fish food extruder machine line

.jpg)

Lima feed machinery offer wet type/dry type fish feed extruder and customized floating fish feed making machine line, Which is suitable for fish, crab,shrimp,cat,dog, pet. Capacity from 30kg/h~5000kg/h