The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity. Main power: 75kw.

The floating fish feed extruder could produce the sink fish feed and floating fish feed, according to different fish feed formular. Fish feed pellet extruders come in various sizes and capacities, ranging from small, hand-operated machines to large industrial-scale equipment. The choice of a particular extruder depends on the scale of the fish

Sep 6, 2020 · Hi lovers, Subscribers of Fish AcademyHere is a detailed Video I promised to upload on floating feed production.

6. Extrusion with steam preconditioning is known as the wet-type fish feed extruder. The wet-type processing needs a boiler to make steam for the conditioner and ripen the raw material in advance. Dry feed pellets are stable for relatively long periods, for convenient storage and distribution. Note: This floating fish feed machine can only work

Aug 15, 2022 · Design, Fabrication and Performance Evaluation of a Single Screw Extruder for the Production of Floating Fish Feed August 2022 Journal of Scientific Research and Reports 28(10):1-10

.jpg)

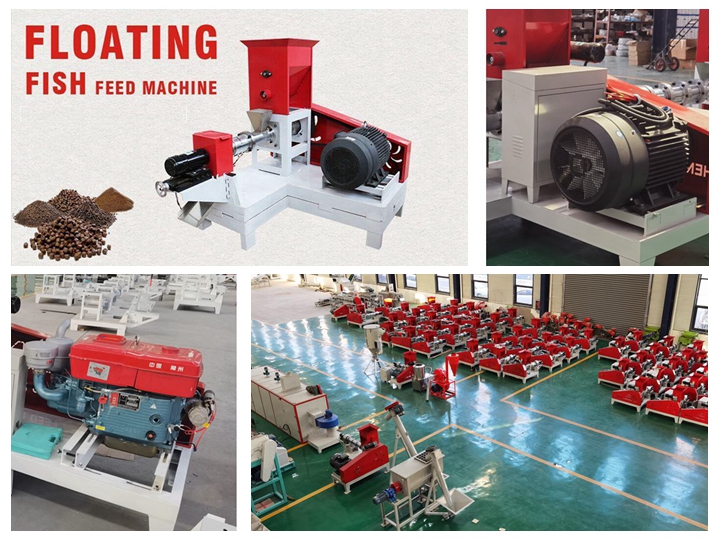

Jul 27, 2020 · Fish feed pellet machines from 40kg/h to 800kg/h. Can be powered by an electric motor or a diesel engine. Different molds and sizes from 0.8mm to 12mm. Suita

.jpg)

It uses grains flour, fish meal as the raw material. The whole fish feed processing line is easy to operate and high automatic. It is suitable for Middle and large-size factories. It use the Double screw extruder to produce the fish feed pellets. Keyword: fish feed extruder machine, fish feed extruder, fish food extruder, fish feed processing

.jpg)

What is the floating fish feed machine? The floating fish feed pellet machine is a machine to carry out various aquatic feed production. Besides, we also have the fish feed processing line available. The size of the feed pellet mill is φ1mm, φ1.5mm, φ2mm, φ3mm, φ3.5mm, φ4mm, φ5mm, φ6.8mm, and various shapes.

.jpg)

Consider After-sales Services when you buy fish feed extruder machine in Nigeria. Sometimes, a slightly higher on how to buy fish feed extruder machine in Nigeria can include extended warranties, maintenance services, or training sessions. These add-ons can save significant costs in the long run. 5. Spare Parts Availability.

A floating fish feed extruder machine is a piece of equipment used in the production of floating fish feed pellets for aquaculture. Floating fish feed is designed to float on the water’s surface, making it easily accessible to the fish being raised. This type of feed is commonly used in fish farms, especially for species like tilapia, catfish

.jpg)

Floating fish feed has a wide range of applications. Fusmar fish feed extruder machine can make high-quality floating fish feed pellets. Whether it is cage fish farming or small pond fish farming. When choosing the ideal fish feed, many factors need to be considered. The most important is type.

.jpg)

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

.jpg)

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

It is a crucial machine for making high-quality fish pellets and pet food. Features of Wet Type Fish Feed Making Machine. 1. This kind of fish feed extruder machine has a simple structure, wide application, and low noise. 2. It can improve the quality and floating time of the fish feed pellets. 3.

Reducing feed waste: Floating fish feed has good water stability, floating in water long for several hours, hence avoiding the dissolution of nutrients in the feed and the sinking of feed into the mud, reducing feed waste to a large extent. According to tests, using floating fish feed can save about 10% of feed than using powered or hard pellet