About Us. HM Feeds Ltd is a Zambian family-owned business established in Kitwe, Zambia. Our modern state-of-the-art factory started its operations in 2017. Our factory specialises in the production of high-quality extruded animal feed in pellet form. Our range of products includes extruded pellet aquaculture/fish feed ( Aqua Tail) and extruded

.jpg)

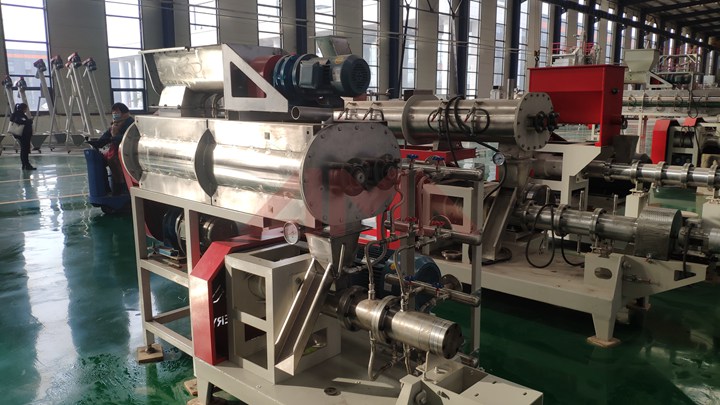

Fish Feed Extruders with Various Production Capacities. Our Fish Feed Extruders are with improved qualities and affordable cost. It includes: dry type single screw extruder, wet type single screw extruder, double screw extruder, ring die fish feed pellet mill, and diesel engine extruder machine.

.jpg)

large scale Largemouth Bass feed pelleting machine in ZambiaFish feed pellet making machine Zambia for high qualitySunwit is a professional fish feed machine manufacturer. We help Tel: 8619337889051

.jpg)

Wet feed extruder is mainly used in large and medium-sized feed processing plants and farms. Our wet fish feed extruder can produce animal feed pellets with a diameter of 0.9-12mm and is also suitable for producing pet food, fish feed pellets, shrimp feed and other animal feed pellets.

guppyl fish extruded feed machine fish pond farming Wet feed extruder is mainly used in large and medium-sized feed processing plants and farms. Our wet fish feed extruder can produce animal feed pellets with a diameter of 0.9-12mm and is also suitable for producing pet food, fish feed pellets, shrimp feed and other animal feed pellets.

Large Fish Feed Production Machine Line Sent to ZambiaLarge Fish Feed Production Machine Line Sent to Zambia - YouTube This is a large-capacity fish feed production that was loade Tel: 8619337889051 Email:lima37@limamachinery-Lima

.jpg)

HM Feeds Ltd is a family-owned business specialising in the production of high-quality extruded animal feed in pellet form. Our factory was established in Kitwe, Zambia, and commenced its operations in 2017. We offer two brands: Happy Tail (pellet dog feed) and Aqua Tail (pellet aquaculture feed). Our products can be found in various stores

.jpg)

Reasonably Priced Fish Feed Pellet Machine in Nigeria We provides wet type fish feed extruder at the prices from $4,900 to US$34,000, depending on what production capacity the customers choose. Similarly, the prices of dry type extruder are lower, from $. Get Price >>.

.jpg)

Large Fish Feed Production Machine Line Sent to ZambiaLarge Fish Feed Production Machine Line Sent to Zambia - YouTube This is a large-capacity fish feed production that was loade Tel: 8619337889051 Email:lima37@limamachinery-Lima

.jpg)

Sunwit is a professional fish feed machine manufacturer. We help small, medium and large-scale fish pellet production clients set-up a fish feed plant that is designed to meet customers‘ specific demands at different capacities. Sinking fish feed machine (500kg-4t/h) The fish feed extruder is a Read More ».

.jpg)

The guppy fish farm come in amazing varieties that promote higher efficiency through saving time and minimizing wastage. The broad selection of guppy fish farm ensures that nobody misses out on their befitting products. They are available for both small-scale and large-scale applications, as well as for personal needs and use.

We help small, medium and large-scale fish pellet production client Email: lima37@limamachinery-Lima Tel: 8619337889051 dry type guppyl fish food extruder in Zambia-Feed Pellets Mill Dry Type Fish Feed Extruder-floating fish feed machine Floating Fish Feed Extruder Machine – Fish Feed Pelletizer Commercial fish feed

.jpg)

Lima Feed Machine Lima Feed Machine was founded in 1989, is a 34 years of development and production experience of fish feed extruder factory. Our main products include dry/wet fish feed production line, diesel fish feed extruder, corn/soybean extrusion line, feather meal extrusion line, fish feed production line, floating fish feed making

.jpg)

Floating Fish Feed Extruder Machine - Fish Feed Pelletizer Commercial fish feed extrusion process refers to the cooked fish feed mixture under high temperature, steam and high pressure through a fish feed extruder in a short time, where high temperature is friction (dry extrusion) or pretreatment and steam injection (wet extrusion).