The German machine manufacturer Amandus Kahl has been manufacturing a new extruder for the production of fish feed and pet food since 2019. The extruder OEE 25 NG (New Generation) was introduced onto the market with a screw diameter of 250mm and a resulting capacity of up to 10t/h.

.jpg)

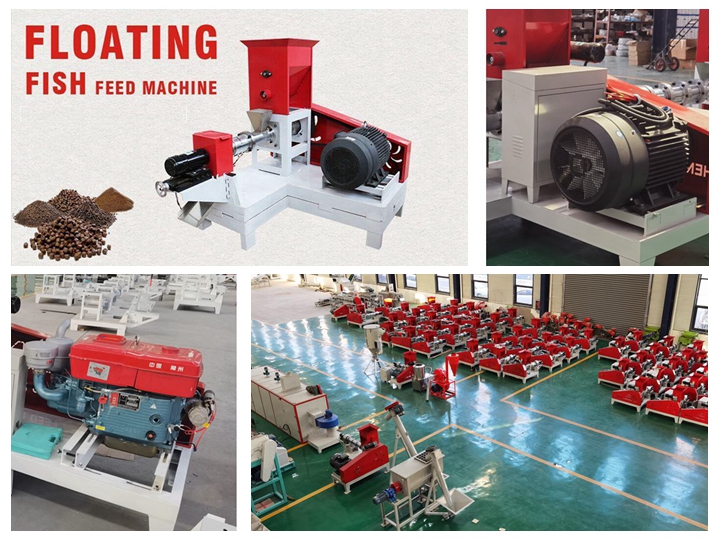

Production Line Advantages. Features of floating fish feed Production Line: 1) Design: Developed by 3D software, analog simulation, and it has been tested by a computer automatically, in order to ensure the accuracy of the design requirements. 2) Concept: Modular function, humanized menu system, and various applications are always our pursuits.

.jpg)

Gupfenstrasse 5. Uzwil. 9240. Switzerland. Contact us. Bühler’s extrusion solutions for human food, pet food and aqua feed manufacturing include weighing, dosing and grinding, cooking and shaping, drying and coating. Global services include process engineering, R&D and local customer service centers.

The floating fish feed machine is to convert soybean meal, rice bran, fish meal, bone meal, corn meal, flour, etc. into fish feed pellets with various shapes by heating and extruding. It has a capacity of 40-350kg/h, even bigger.

.jpg)

05. Fish feed machine can get the higher-protein animal feed, and easy to digest. 06. The wet type of fish machine has good self-cleaning effect without disassembly. 07. It has high water content, wide application range, can produce high oil and moisture materials. 08. This type fish feed machine is mainly used in aquatic feed, pet food and

.jpg)

Our cold (dry) feed extruder has many advantages as follow: 1. easy opertion and convenient maintainance. 2. long life to run. 3. high temperature in the extruding chamber (max. 160centigrade) according to yoru demand to killing urea enzyme of soybean ,long time storage for rice bran , or Cotton Seed De-Toxin.

.jpg)

5 days ago · Pellet Mill Vs. Extrusion of Fish Feeds. The process of pelletization happens inside a pellet mill. It involves creating pelleted feeds by compression of raw material, which is in powder form. This compaction happens in the presence of some moisture, temperature and pressure. Pelletized feeds are dense and heavy and thus they sink.

.jpg)

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

Our range of floating fish feed machine products include 1.5-12t/h floating fish feed extruder, twin screw extruder machine, single screw extruder machine, wet screw extruder machine, and all auxiliary equipment for floating fish feed processing systems.

.jpg)

This twin-screw extruder is the ideal companion to recipes with a large volume of meat slurries or fresh meat. The New ANDRITZ twin screw extruder ensures complete utilization of starch and ensures total material discharge, for the best hygienic conditions as well as quick recipe changes. Watch our product animation to see the NEW ExTS 718 in

.jpg)

Aqua feed solutions you can rely on. The key to producing quality aqua feed without losing essential nutrients is a gentle extrusion process. Our extrusion solutions give you precise control over the cooking and shaping process so that you can produce fish feed of the highest quality.

.jpg)

Nov 13, 2023 · Extrusion is a fish feed manufacturing process used to shape and assemble feed. It involves forcing a mixture of ingredients through a die under high heat and pressure. The extruded feed can then be shaped and sized to meet specific needs, such as floating or sinking pellets. Fish Feed Extrusion Process Flow.

.jpg)

The extruder is a long, cylindrical device that contains a screw-like device called an auger. The auger is responsible for moving the feed mix through the extruder. As the feed mix moves through the extruder, it is subjected to a series of heated metal plates. These plates heat the feed and cause it to expand.

.jpg)

After more than 20 years of experience with extrusion systems, AMANDUS KAHL has developed the extruder OEE 25 NG to meet the increasing demands of the fast growing fish and animal feed markets. The new extruder features AMANDUS KAHL stop bolt technology for ideal mixing and venting in the first cylinder section.