Fish Feed. Clextral extrusion systems efficiently produce high-energy feed with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility. Extruded feeds are produced to match fish feeding habits (floating, neutral buoyancy or sinking) to energize feeding and reduce waste. We offer an output range from 25 to

NEW design pet dog cat food extruder for Floating Fish Feed Pellet Making Machine Fish Feed Production Line $1,500.00. Min Order: 1 set. CN Supplier . 6 yrs. 5.0 /5 ·

Floating Fish Feed Extruder Machine 3-4T/H. Floating Fish Feed Pellet Making Machine 4-5T/H. Floating Fish Feed Pellet Mill 6-7T/H. Fish Feed Pellet Extruder 8-10T/H. Floating Fish Pellet Machine For Sale 10-12T/H. Sinking Fish Feed Machine. Menu Toggle. Fish Feed Processing Line. Sinking Fish Feed Pellet Mill 0.6-1.2T/H.

.jpg)

Buy the best extruder and microwave machines for your business from Shandong Dongxuya Machinery Co., Ltd. Explore a range of high-quality products like heat pump drying machine, microwave drying and sterilizing machine, puffed snack food machine, pet food machine, and more.

.jpg)

This customer interested in SFE60C and SFE70B fish feed extruder. His demand is production capacity <250 kg/h and the pellets must float. According to customer needs, This 200kg/h fish feed making set contains: mixer machine, fish feed extruder, pellet dryer and oil sprayer. Photos: 200kg/h small fish feed making plant for Tanzania.

.jpg)

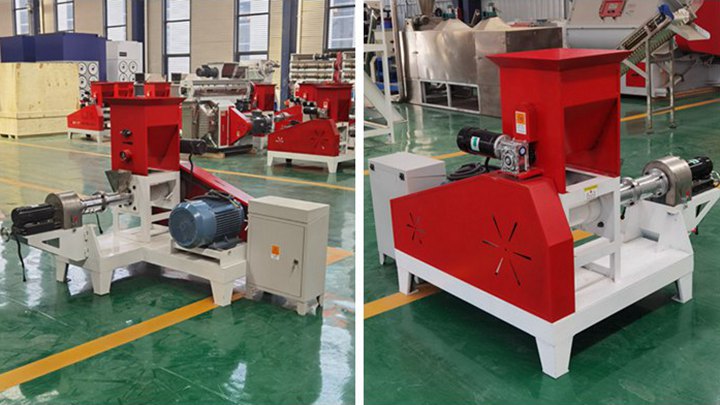

200KG/H Small Fish Feed Making Plant for Tanzania. This customer interested in SFE60C and SFE70B fish feed extruder. His demand is production capacity <250 kg/h and the pellets must float. According to customer needs, This 200kg/h fish feed making set contains: mixer machine, fish feed extruder, pellet dryer and oil sprayer.

.jpg)

Mikim continues to provide professional feed extruders to global feed manufacturers and farms. Currently, Mikim’s best-selling products include DGP series, LX series, single-screw extruders and twin-screw extruders. Feed extruder is suitable for producing floating fish feed, sinking fish feed, pet feed, puffed food, etc.

.jpg)

Save money on feed processing machines when you shop for floating fish food extruder atLima.com. Discover permanently low prices when you buy direct from Chinese wholesalers.

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

05. Fish feed machine can get the higher-protein animal feed, and easy to digest. 06. The wet type of fish machine has good self-cleaning effect without disassembly. 07. It has high water content, wide application range, can produce high oil and moisture materials. 08. This type fish feed machine is mainly used in aquatic feed, pet food and

Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency.The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met. Quality control is also pivotal in fish feed manufacturing. Sinking Fish Feed Quality Assurance

.jpg)

A. The cost of a Fish Feed Extruder can vary widely depending on its size, capabilities, and complexity. Most of the price of Fish Feed Extruder ranges from US $ 300 to $ 100000 per Set. It's important to research and compare different models and features to find the best Fish Feed Extruder for your needs and budget. Q.

.jpg)

Oct 15, 2018 · Produce floating fish feed, slow-sinking fish feed. Using different molds, can also produce pet food, like dog, cat food and also animal poultry feeds. The wet extruder is used for extrusion of full fat soybean, corn, piglet, soybean meal, cotton seed meal, rice bran etc.

.jpg)

Gupfenstrasse 5. Uzwil. 9240. Switzerland. Contact us. Bühler’s aqua feed production solutions include complete plant design and installation for producing a full range of fish feed pellets, including floating, sinking and slow sinking feed for shrimp, salmon, trout, seawater fish and more.

Hence, you must select a machine that can produce the right type of pellets for your specific fish. for floating pellets, you need floating fish feed extruder, for sinking pellets, you need sinking fish feed machine. Understanding the Manufacturing Process. In the fish feed making process, raw materials are first mixed and ground into a fine