Dec 26, 2023 · small scale fish feed processing machine in Kenya . small manual sinking fish feed production machine cost floating fish feed extruder line equipment 1 ton hour sinking fish feed pellet mill, US $ 89899 - 89999 / Set, Manufacturing Email: lima37@limamachinery-Lima Tel: 8619337889051. Get Price >>. 26 12 2023.

.jpg)

fish mash feed machine design nigeria 1-2ton/h Small Animal Feed Manufacturing Process Design. 1 ton/h feed milling machine. $10,000~$20,000. 3 ton/h animal feed process company (both making mash feed and pelleted feed) $60,000. 5 ton/h cattle feed process line. $70,000~$80,000. 10 ton/h feed manufacturing plant. over $100,000.

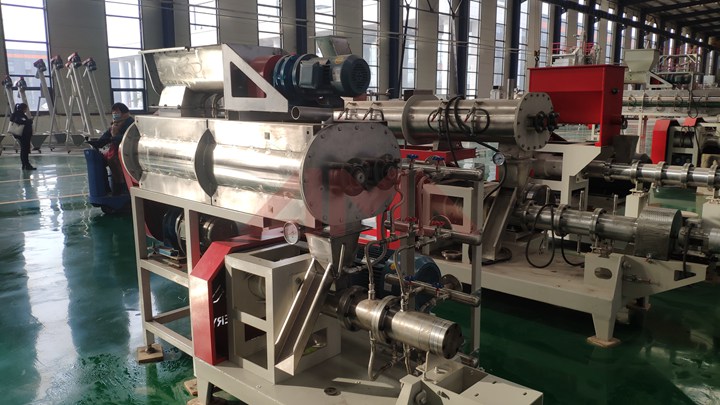

The fish feed processed by our floating fish feed pelleting machine has the advantages of high hardness, smooth surface, complete internal ripening, good palatability, etc. It can effectively improve the digestion and absorption of nutrients in the feed pellet. Users can also choose different discharge apertures according to the needs of their

We provide floating fish feed extruder to Nigeria at the prices from US$2000 to US$7500, depending on what production capacity the customers choose. By the way, as the fish feed machine expert, we can customize the production capacities according to customers’ requirements.

the results show high machine efficiency of 93% and pelletizing efficiency of 96.3%. The production cost of the developed machine is ₦90,000 Nigerian naira (approximately $294). The machine is affordable and simple to maintain and therefore, it is recommended for small and medium scale fish farmers in both rural and urban areas.

.jpg)

fish mash feed machine design nigeria 1-2ton/h Small Animal Feed Manufacturing Process Design. 1 ton/h feed milling machine. $10,000~$20,000. 3 ton/h animal feed process company (both making mash feed and pelleted feed) $60,000. 5 ton/h cattle feed process line. $70,000~$80,000. 10 ton/h feed manufacturing plant. over $100,000.

.jpg)

The fish feed processed by our floating fish feed pelleting machine has the advantages of high hardness, smooth surface, complete internal ripening, good palatability, etc. It can effectively improve the digestion and absorption of nutrients in the feed pellet. Users can also choose different discharge apertures according to the needs of their