.jpg)

wet type Largemouth Bass twin screw extruder machine in Uganda-Fishfeedpelletizers wet type twin screw extruder machine horse kenya-Lima Fish The pellet size can be from 0.9-15mm to feed different size fishes. High capacity and top quality products, Wet type Sin +8619337889051 Email: lima37@limamachinery-Lima HOME

small Largemouth Bass feed machine in Uganda-Fishfeedextruders Fish fish feed extruders supplier in Uganda-FishfeedextrudersNov 28, 2023 · This is in accordance with the feed material grinder as well as the Dry Type Fish Feed Machine. Photo 3 Email: lima37@limamachinery-LimaTel: 8619337889051 Home Products Feed crushing machine

Twin Screw Extrusion lines can process a much wider range of materials and have different applications. The advantages of Twin Screw extruders are higher mixing capabilities, better control of process parameters, high speed of processing and better processing of much harder materials like PVC.

.jpg)

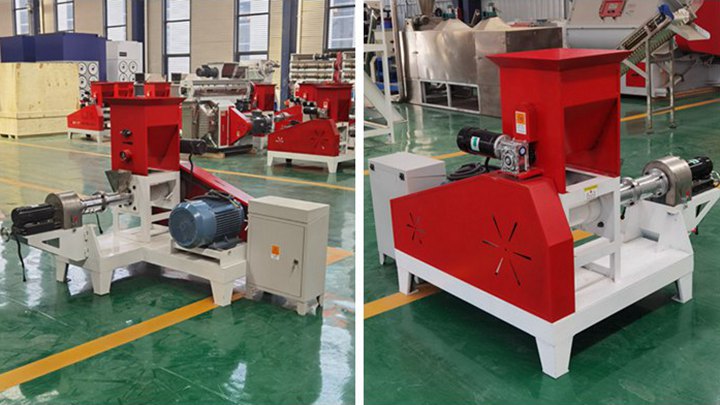

Largemouth Bass feed extruder machine parts low cost 100kg/h fish feed extruder machine parts Feed size 8 mm in. The cost of fish pelleting machine depends on the capacity of the machine. We provide small floating fish feed extruder to Nigeria at the prices from US$2000 to US$7500, capacity from 50 to 400kg/h. Lately, the cost of fish feed in.

co-rotating twin screw extruders from Ø 55 to 170 mm Thanks to our long-term experience and spurred on by the need to cater to the ever-changing requirements of our customers, we have improved the quality and performances of our machines, implementing them in terms of energy efficiency and versatility to process a variety of raw materials and

.jpg)

Manufacturer: Leistritz. 50mm Leistritz Model ZSE50GG counter rotating twin screw extruder. Driven by 46kw AC motor 2200 rpm, 460 volt, AC input (missing HMI for operator control). Has temperature control panel, motor drive and electrica... Hainesport, NJ, USA. Click to Request Price.

.jpg)

Twin-screw extrusion (TSE) is the standard for mixing and compounding in polymer processing and has expanded into other applications for new material development. TSE offers a high level of process flexibility, more control of process parameters, and can produce a wider range of products.

.jpg)

Small, simple, and scalable. Achieve reliable scale-up, reduced time to market, and controlled, continuous processing using Thermo Scientific compounders and extruders. Our twin-screw compounders offer flexible compounding configurations for small batches for either pilot scale production or low volume manufacturing and are well-suited for

Twin-screw extruder Our multifunctional PolyTwin, EcoTwin and CompacTwin twin-screw extruders offer flexible, reliable 24/7 processing for your breakfast cereals, food ingredients, pet food and aqua feed products. Back Key benefits Low-cost lifetime operation

The ZE BluePower twin-screw extruder series stands out for numerous innovative features in terms of energy efficiency and process engineering. This series is designed to meet the most demanding market challenges as to output rate, product quality, process reliability and flexibility.

The new standard for extrusion excellence. Our latest range of premium equipment for high quality production lines. Evolum+ twin-screw extruders are equipped with advanced technology to give our customers new levels of throughput, flexibility and control while ensuring optimum process stability and maximum food and non-food product quality.