.jpg)

Fish feed pellet making machine like tilapia fish feed machine and Therefore the demand for aqua feed, especially fish feed, is growing fast too and so the... LEARN MORE

RCPH120*2 floating fish feed extruder machine is the third generation of new twin-screw extruder machine developed by Richi Machinery on the basis of digesting and absorbing foreign advanced technology. Its power configuration is 90KW, and the output of processing aquatic feed is 3-4 tons per hour. It can meet the current production needs of

The price of 1 ton floating fish feed making line is usually 30,000-150,000 USD. According to your needs, we can also provide custom design services. Pls send me a proforma incoice include transport price for 2-3t/h floating fish feed production line. The 2-3t/h floating fish feed line cost is USD 80,000-500,000.

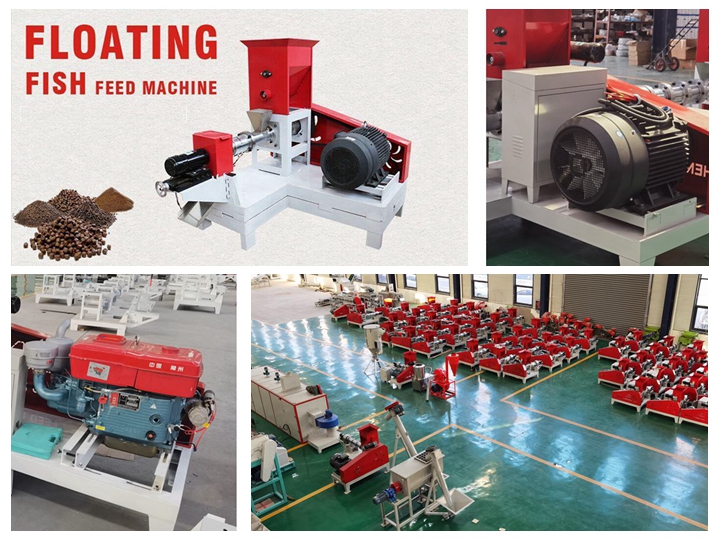

We focus on dry type floating fish feed pellet machine here. The single-screw, dry type machine produces floating fish feed pellets for fish, tilapia, catfish, shrimp, crab, turtle, and goldfish. High temperature in the floating fish feed pellet machine puffs the pellets, allowing them to float for 24 hours. Pellet sizes range from 0.9mm to 15mm.

.jpg)

Pellet mill – Changzhou Farthest Machinery Co.,LTD. Asia, Eastern Europe, Mid East/Africa, North America, Western Europe. Inquire Steam Conditioner Sinking Fish Feed Pellet Mills for Sale. US$ 52800.00 / Set. 1 Set (MOQ) Inquire Now Advanced Technology Tilapia Fish Farming Feed Pellet Making Machine. US$ 60000.00 / Set. 1 Set (MOQ

.jpg)

Tilapia Fish Feed Pellets Formulation Fish Feed Pellet Machine Sep 24, 2019 · Floating fish feed pellets are ideal for tilapia, which feeds on the surface layer of water. Commercial fish feed particles are produced by extruding (floating or buoyant) or pressure settling (sinking) feed.

RICHI 4-5t/h floating fish feed pellet making machine is a kind of twin-screw feed extruder, mainly used in the production of aquatic feed, pet feed, livestock and poultry extruded feed. Extrusion and puffing is a high-temperature, high-pressure, instantaneous, and ripening process.

.jpg)

Aquarium Tilapia Fish Food Machine - Shop for a aquarium tilapia fish food machine from a Chinese wholesaler at and find a wide selection of pet food processing machines that meet +8619337889075 lima38@limamachinery.com

.jpg)

500-600kg/h small scale fish feed pellet making production machine drying floating tilapia fish feed machine in China $1,860.00

.jpg)

RICHI floating fish feed machine is suitable for processing viscous, oily, and high-humidity aqua feed products, and can provide ideal solutions for low-starch aquatic feed, and pet food with high fresh meat content. Consult Now.

floating fish pellet machine for sale. floating fish feed, floating fish feed Suppliers and Hot sale floating fish feed pellet machine fish feed making machine in Nigeria US $850.00-$1150 / Set 1 Set (Min. Order) 2 YRS Hebei Muvan Mach fish feed anf heating machines.

Jul 24, 2015 · Agriculture / Fish Feed Machine-dry Type by azeuspelletmill ( f ): 9:48am On Jun 29, 2015. 1. The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets . Tilapia Fish Feed Pellets Formulation Fish Feed Pellet Machine

Our ring die pellet mill with conditioner is also available to make high-quality fish feed pellets. Fish Feed Extruder Features and Advantages 1. Floating, sinking, and slow-sinking aqua feed can be produced by adjusting feed formulation and related parameters of expansion. 2. The finished pellets can keep floating for 3-15 hours without

Jun 18, 2021 · The particles were preserved in a dry, sterile container; 2mm skretting tilapia fish feed pellets were obtained from Durante Fish Industries limited with nutrient composition of 35% crude protein as well as 18.5MJ gross energy per kg feed was formulated as prepared diet by adding 2.0 g, 4.0g, 6.0g dosage treatment of PSM separately to 1 kg of

Floating fish feed pellets are desirable for tilapia which feed from the surface layers of water. Extruded feed pellets are more expensive due to the higher manufacturing costs.