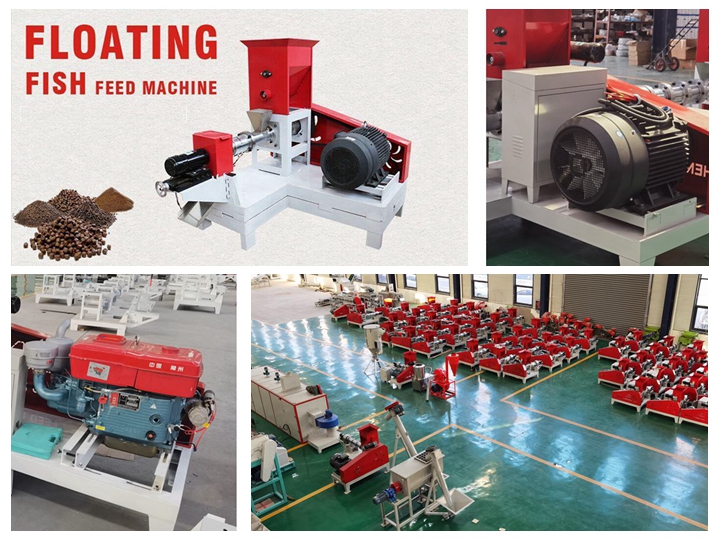

05 List of 4-5 t/h floating fish feed equipment. The following is only the core fish food processing machine list of the standard 4-5t/h floating fish feed plant, and the equipment can be configured according to the actual product type, process, formula and investment budget.

.jpg)

The majority of fish feed manufactured is in the form of compressed pellets. The pelletized feed has many advantages, including less feed waste, more uniform feed intake, and the removal of growth inhibitors.

.jpg)

Jul 21, 2014 · Weight gain (pounds per fish) and feed conversion ratio were 1.13 and 1.67, respectively, for fish fed a 32% protein feed; 1.18 and 1.65, respectively, for fish fed 28% protein. SUMMARY Considerable research has been conducted over the last two decades on plant-based catfish feeds, including the evaluation of plant-based feeds containing

.jpg)

As preparation for extrusion, the feed mixtures are precooked by means of a special two-stage conditioning process in accordance with the different starch properties. The principal machine is the retention conditioner. In this machine, the retention time of the feed is continuously adjustable between 60 and 180 seconds, using a special pile-up geom See full list on akahl.com Since 2019 AMANDUS KAHL has been manufacturing a new generation of extruders. The extruder type OEE 25 NG(New Generation) can cover an output range of up to 10 t/h in large-scale industrial applications. The new KAHL extruder, for example, features the proven KAHL stop bolt technology in the first cylinder section, which enables homogeneous product... See full list on akahl.com In our KAHL vacuum coaterthe fish pellets are refined with fats and liquids. The sequence of the individual process steps in vacuum coating can be tracked and retraced by the operator. As a result, the parameters can be adjusted on the basis of the extrudate properties or formula. This refers in particular to the important steps of liquid proportio... See full list on akahl.com The continuous quality control of the finished product is ensured by a software system for batch traceability. It forms the basis for a total quality management and allows storing more than 1,000 formulae and retracing the production data. With the help of continuous batch marking in the process database, it can be traced which production adjustmen... See full list on akahl.com

There is a clear vision from the country to become self-sufficient or at least largely self-sufficient for fish through aquaculture,” he adds. The new plant, which has a capacity of 35,000 tonnes of feed, is located at Siavonga on Lake Kariba, close to the main fish farming areas in both Zambia and Zimbabwe.

.jpg)

May 23, 2017 · Adopting alloy steel as material, FANWAY dry type fish feed extruder has been widely used in small-scale and medium-scale fish farm or feed plants to produce aqua feed and also dog/cat pet feed in

.jpg)

Above simple methods can initially determine the quality of the feed, if you are a manufacturer of fish feed pellets, you need to pay attention not only to the cleanliness and hygiene of the feed materials, plant layout, but also to select the top quality equipment.

Apr 5, 2023 · Maharashtra Feeds recently inaugurated a new state-of-the-art floating fish feed plant in Lucknow, Uttar Pradesh, India. With a production capacity of 35,000 metric tons per year, the company aims to serve the North, Central, East and parts of Western India. The plant is equipped with modern and fully automated equipment.

.jpg)

• Vertical mixers provide fish feed plants to save place. Introduction to Production Steps of Aquatic Feeds (Mixing) • Horizontal mixers, welt mixers provide;

For species such as tilapia and trout, floating meals are widely employed. Floating feed facilities generate floating fish feed pellets using specialised extrusion or pelleting equipment. Sinking Feed Plant: Sinking feed plants create fish feeds that sink to the water’s surface. These feeds are appropriate for bottom-feeding fish such as

.jpg)

The final products have unique shape and good taste, high nutrition and smooth textures. For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment. This dry type floating fish feed machine is an ideal for small and medium fish farm holders or feed processing plant.

Screened product is stored in a bagging bin, weighed and then meticulously packaged for distribution. Cremach produces cutting-edge fish feed machinery for optimum livestock nutrition and performance. Through advanced equipment and quality assurance, we provide optimal feed, supporting healthy growth and development of aquaculture fish.

.jpg)

Big scale long service life 400,000 tons per year animal poultry livestock feed production plant project; Large turnkey poultry pig fish feed processing plant project with an annual output of 200,000 tons in China; Complete annual output of 120,000 tons cattle feed mill processing plant project in China

.jpg)

Our floating fish feed production line is the complete process of fish feed production, including fish feed machine, fish feed grinder, fish feed mixer, fish feed dryer and other equipment, this fish feed production line equipment is for corn, corn production of commercial pellets, grass, grains, protein, syrup, etc., and finally form a variety

STLP300/STLP400 small feed pellet plant is a small scale pellet feed plant that produces 600-800kg/h and 800-1000kg/h animal feed pellets, widely used to produce feed pellets for cattle, cow, sheep, goat, horse, chicken, broiler, duck, goose, bird, fish (sinking fish feed pellets), and so on. It is mainly composed of small hammer mill, small