The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

.jpg)

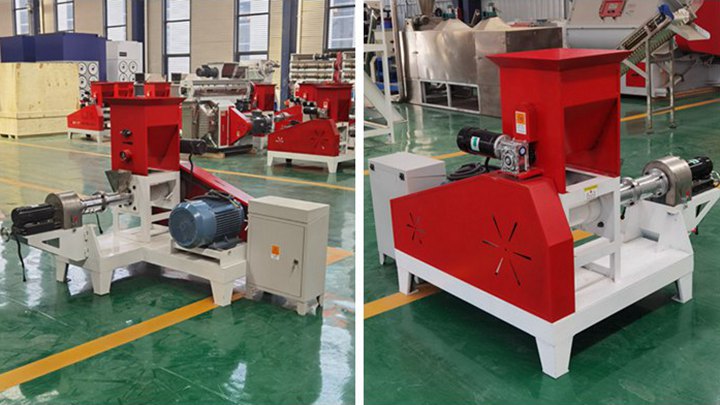

May 23, 2017 · Adopting alloy steel as material, FANWAY dry type fish feed extruder has been widely used in small-scale and medium-scale fish farm or feed plants to produce aqua feed and also dog/cat pet feed in

.jpg)

As a floating fish feed extruder machine manufacturer, in order to meet floating and sinking fish feed, feed Production Line supplier developed twin screw extruder design, is widely used for produce high-grade aquatic feed pellets for fish, catfish, shrimp, crab, lobsters, etc.Food extruder production process can produce both floating and sinking fish feed pellets.

1) Grinding fineness: Proper particle size of ground materials can contribute to lower energy consumption of a feed mill, facilitate the subsequent conditioning process, increase the water stability of aquafeed pellets, and eventually obtain nutritional aquafeed that benefits the digestibility of aquatic animals. 2) Size of feed pellet: It is depen See full list on feedmachinery.com Both pelleting process and extrusion process are adaptable to aquafeed production. As the development of aquaculture, however feed extrusion technology is more and more popular in the aquafeed production because of its well- balanced nutrition, the excellent water stability, and most of all, the environment friendliness. Usually, the common (pre-gr... See full list on feedmachinery.com Aquafeed production solutions are different from case to case. They should be tailor-made on the basis of a good understanding of the customers’ needs, the local market’s requirements and the aquatic animals to be cultivated. The equipment and process applied for an aquafeed mill shall be optimised by considering the long-term sustainable profitabi... See full list on feedmachinery.com

Apr 1, 2004 · Fig. 1: Zones of a single-screw extruder. Fig. 2: Protein molten phase and swollen starch granules. Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey.

.jpg)

Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet extrusion). As a technological

.jpg)

CE 2020 New Type Maize Meal Feed Material Extruders Food Fish / SPH Series Fish Feed Soybean Extruder for Pet Food. new. Manufacturer: Luodate; SPH series Fish Feed Extruder Capacity (t/h): 3-10 Power (kw): 160-315 Application: suitable for all kinds of floating aquatic feed processing. soybean meal and oil extruders pet food / small animal

.jpg)

This animal feed puffing machine is widely used for producing grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab and pets food for dog, cat, etc. The finished feed pellets can be made with different sizes 0.9-25mm.

.jpg)

Binders: Ingredients like wheat flour and starch are used to give the feed pellet its shape and help it hold together underwater. 7. Amino Acids: Lysine and methionine, among others, are added to ensure a balanced amino acid profile, crucial for optimal fish growth. 8.

wet feed extruder DSP Series. single-screw fish for aquaculture. Contact. Production capacity: 0.18 t/h - 5 t/h. Wet type fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab. cat. dog and etc. Grain materials employed in fish feed pelletizer are such

.jpg)

05. Fish feed machine can get the higher-protein animal feed, and easy to digest. 06. The wet type of fish machine has good self-cleaning effect without disassembly. 07. It has high water content, wide application range, can produce high oil and moisture materials. 08. This type fish feed machine is mainly used in aquatic feed, pet food and

Wet type fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab, cat, dog and etc. Grain materials employed in fish feed pelletizer are such as wheat, soybean, cake and other leftovers and etc., moreover puffing pellets produced by the pellet machine can float on the water surface without dissolution

Wet type fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab. cat. dog and etc. Grain materials employed in fish feed pelletizer are such as wheat, soybean, cake and other leftovers and etc.. moreover puffing pellets produced by the pellet machine can

.jpg)

Sinking Fish Feed Machine As a kind of feed making machine, the wet type fish feed extruder can make fish feed pellets from corn, bean pulp, corp stalk, grass, rice hull and so on. The wet type fish feed extruder machine is widely used in making both floating fish feed and sinking feed pellets for aquaculture farms, feed mills, livestock farms

There are many kinds of floating fish feed mill plant— the 1-2t/h, 3-4t/h, 4-5t/h, 6-7t/h, 8-10t/h, 10-12t/h, etc., and these kinds have hundreds of customized designs in total. No matter what demands you put, we can always assemble a floating feed plant for you. Floating fish feed mill cost:80,000-3,000,000 USD.